Infrastructure

Foundry Facilities

Raw Material Storage

Our raw material storage spans 4,624 sq. ft., offering

a well-organized

and spacious facility designed for smooth inventory handling and efficient material

management.

Foundry

At the core of our manufacturing strength lies our advanced Foundry facility.

Covering

25,670 square feet, it is equipped with five

high-efficiency

induction furnaces engineered for precision casting. With a robust monthly melting

capacity of 850 tons, this facility forms the

foundation

of consistent quality and large-scale production.

Pouring

Precise control of temperature and rotational speed during the centrifugal pouring

process ensures uniform metal distribution and consistently superior casting

quality.

Metallurgical Lab

Spectrometer

Advanced spectrometer analysis is used to precisely verify raw material composition,

ensuring optimal metallurgy that enhances liner strength, durability, and long-term

performance.

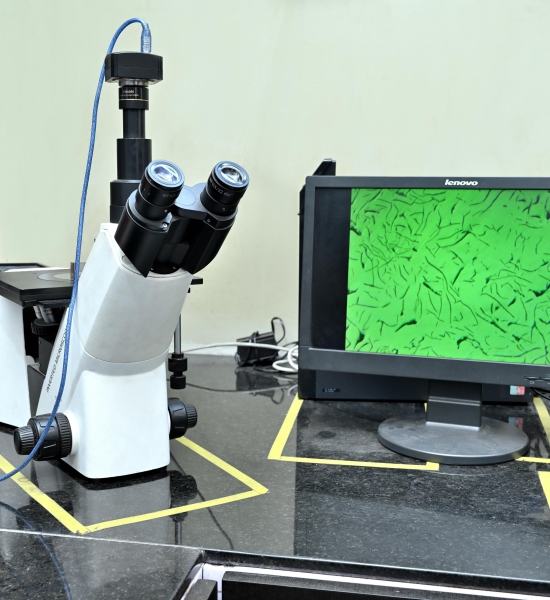

Microscope

Microscopic examination is carried out to closely analyze the liner microstructure

and

maintain optimal graphite formation. This controlled approach improves mechanical

strength and reflects our commitment to consistent quality and high performance.

Hardness Tester

Hardness testing is performed to accurately verify material strength and

consistency,

ensuring every liner meets defined quality standards and delivers reliable

performance.

Machining Area

Machining Area

Our machining facility spans 46,938 sq. ft. and is

equipped with

advanced CNC VTLs, CNC machining centers, centerless grinding machines, plateau

honing,

CNC boring, and CNC turning machines. The setup is further supported by in-house

heat

treatment and phosphating facilities to ensure precision, durability, and surface

quality.

Quality Control

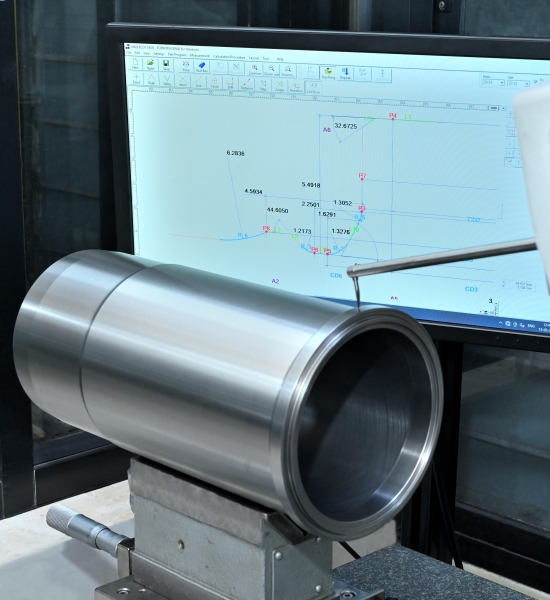

Contracer

High-precision measurement is carried out using a Mitutoyo contracer to accurately

inspect

grooves, radii, and angular profiles on liner surfaces, ensuring dimensional

accuracy and

adherence to strict quality standards.

Digital Height Gauge

A high-precision Mitutoyo digital height gauge is used to accurately measure

critical height

parameters, ensuring dimensional consistency and superior quality in every cylinder

liner

and sleeve we produce.

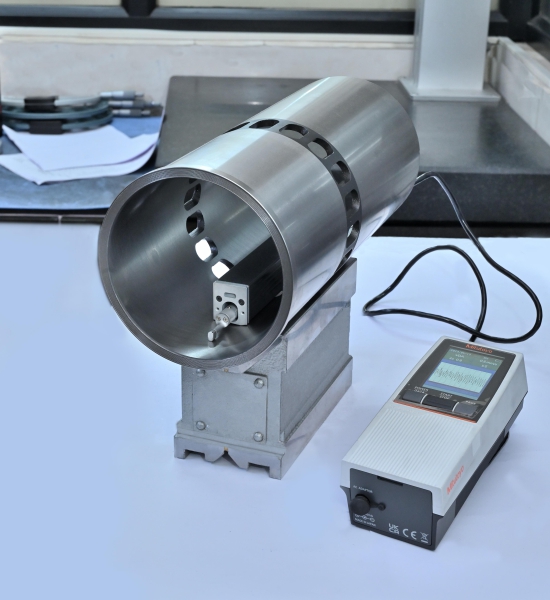

Surface Roughness Tester

Surface roughness is precisely measured at each final machining stage to ensure

smooth liner

and sleeve finishes, enabling optimal piston movement, improved engine efficiency,

and

consistent performance.

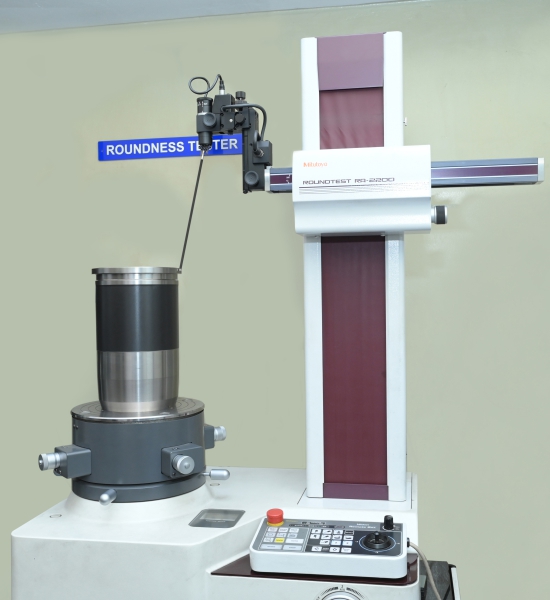

Roundness Tester

A high-precision Mitutoyo roundness tester is used to accurately evaluate critical

GD&T

parameters, including roundness, cylindricity, straightness, concentricity, and

runout.

Its precision turntable enables accurate centering and leveling for reliable

measurement

results.

Packing Area

Packing Area

Santosh Auto-Part operates a dedicated 18,000 sq. ft.

packing area

equipped with automatic ultrasonic cleaning machines and a well-organized storage

setup,

ensuring safe packaging and a superior delivery experience.